Polyethylene Blown Tubular Film

Polyethylene PE Blown Film

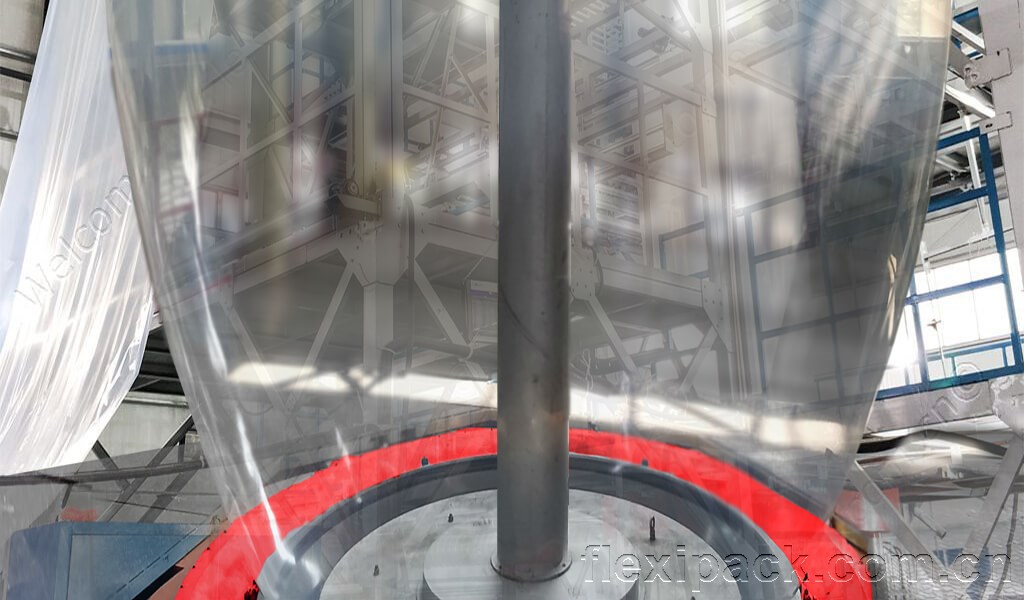

Blown Tubular Film Extrusion is a common method of film manufacturing industry

Blown Tubular Film Extrusion is a common method of film manufacturing industry, HDPE, LDPE and LLDPE are the most common resins material in blown film extrusion industry. Flexipack makes Blown Tubular Film in large fold diameter up to 4,000 millimeters (13 feet), in its Tubular shape, it can be used for industrial packagings, like flexitank for oil, wine, and much other liquid transportation or for temporary storage; or sealed one end to make Jumbo (Bulk) film bag as liner for barrel container to anti-leakage. By cutting into up to 8,000-millimeter-width (26 feet) sheet, the Blown film will be most commonly and widely used. In the agriculture field, Greenhouse is one of the largest plastic film consumption, and it does of landscape film, crop forcing film, silage film. In a wooden field, as a wrapper to keep the lumber away from moisture while keep clear to see their appearance.

Specification

- Thickness: 115 micron to 250 micron (4.5 mil to 9.8 mil)

- Fold Diameter: up to 4,000 mm (13 feet),

- Shipping status: on Roll

- Weight and Length per Roll: As required, 860 kg (1,900 lbs) in normal

- Extrusion method:Multilayer co-extrusion

Applications

Our Blown Film is widely used in various fields: Agriculture

- Greenhouse

- Row cover

- Polytunnel Plant

- Sun selector UVA film

- Anti UV Screen Shading Net House

- Anti-fog film

- Silo bags film

- Silage bag

- Mulch film

Logistics and Transportation

- Food grade liner film for packing bags

- Flexitank liner for liquid transportation and storage

- Flexible liner for railway container and standard container

- Anti-dust cover for indoor warehouses and outdoor storage yards

- Rain hood for Trucks

Forestry and Horticulture

- Green house (winter jacket) for flowers and trees

- Lumber (timber) bag

- Lumber warapping film

- Pallet covers (anti-rain and anti-dust hood)

- Plants Cultivate House

Quality Materials of Blown Films

We only use new and good quality materials

Flexipack always to purchase good HDPE, LDPE and LLDPE granular materials from qualified suppliers for extruding and blowing our Tubular Film in the proper quality to meet our high-end clients’ requirements for the excellent performance in service. ExxonMobil, China Petroleum and other some famous brand will be our priority suppliers. Good products come from good materials is the ever truth what we trust.

Specification

Materials and Brands We have been using

*All listed Logos and Trademarks are property of the registrants.

Productivity

Our Multi-layer Co-extrusion Blown Film automatic production line has high productivity. The extrusion quantity is more than 30,000 kg (66,000 lbs) per day with a folding diameter up to 4,000 mm (13 feet) and thickness from 115 microns (4.5 mils.) to 250 microns (9.8 mils.). This will satisfy our clients with variable purchase quantities and on-time delivery.